Vortex Tubes

Vortex Tubes are ideal for industrial spot cooling and process cooling. Able to cool instantly, Vortex Tubes use compressed air separated into hot and cold air streams to produce up to 6000 BTU/hr (1757 watts) of refrigeration, as well as temperatures as low as -40°C (-40°F).

Performance is easy to adjust and the inlet air pressure and ratio of cool air to exhaust are variable. As well as this, cooling capacities range from 100 – 6000 BTU/hour (29 – 1757 watts). If Vortex Tubes are required for heating, this can be done by changing the hot exhaust air to be expelled as part of the application.

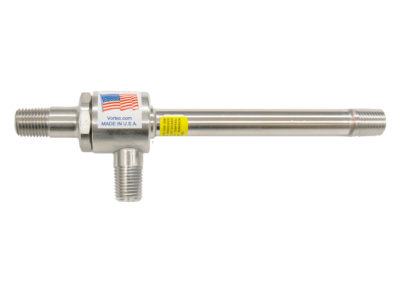

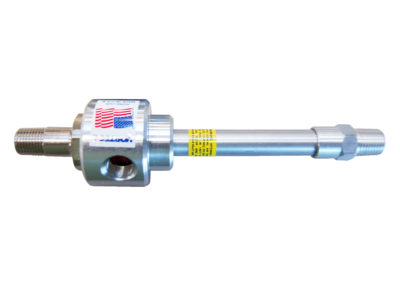

Vortex Tubes are compact and come in models ranging from 150mm to 330mm (6 to 13 inches). They have no moving parts meaning they are both inexpensive and highly reliable.

Enquire nowFeatures & Benefits

Features

- Reduces compressed air inlet temperature by up to 37.7°C (100°F).

- Cools up to -40°C (-40°F).

- Can also heat up to 93°C (200°F).

- Available in aluminium (208 and 308 ) and stainless steel (208SS) models.

- Cycle repeatability within +/- 1deg.

- No electricity is required.

- Replacement generators are available if cooling needs to be modified or if contamination occurs.

Benefits

- Instant cooling.

- Lowest cost per unit of refrigeration compared to any other cooling technique.

- Lowest maintenance requirements compared to any other cooling technique.

- Fully adjustable and easily moved around the site.

- Able to fit in confined spaces.

- No refrigerants or chemicals are needed, and environmentally friendly.

- Easy to install, no electrical connection needed.

Specifications

Specifications

| Specification | Cooling Capacity (Watts) | Air Consumption @ 6.9 bar (slpm) | Inlet Size (inch) | Inlet (Female or Male) | Material of Construction |

|---|---|---|---|---|---|

| 106-2-H-BSP | 29 | 57 | 1/8"BSPP | F | Brass/Stainless Steel |

| 106-4-H-BSP | 59 | 113 | 1/8" BSPP | F | Brass/Stainless Steel |

| 106-8-H-BSP | 117 | 226 | 1/8" BSPP | F | Brass/Stainless Steel |

| 208-11-H-BSP | 188 | 311 | 1/4" BSPP | F | Aluminium |

| 208-15-H-BSP | 264 | 425 | 1/4" BSPP | F | Aluminium |

| 208-25-H-BSP | 440 | 708 | 1/4" BSPP | F | Aluminium |

| 208-11-HSS-BSP | 188 | 311 | 1/4" BSPP | M | Stainless Steel |

| 208-15-HSS-BSP | 264 | 425 | 1/4" BSPP | M | Stainless Steel |

| 208-25-HSS-BSP | 440 | 708 | 1/4" BSPP | M | Stainless Steel |

| 308-35-H-BSP | 777 | 990 | 1/4" BSPP | M | Aluminium |

| 328-100-H-BSP | 1758 | 2830 | 1/2" BSPP | M | Aluminium/Brass |